The automated riveting machine is revolutionising production across multiple industries, ensuring precision, consistency, and efficiency in fastening processes. Expert Technologies Group offers cutting-edge solutions to meet the demands of various sectors, helping businesses streamline their operations. This article examines the applications, benefits, and technological advancements driving the adoption of automated riveting systems.

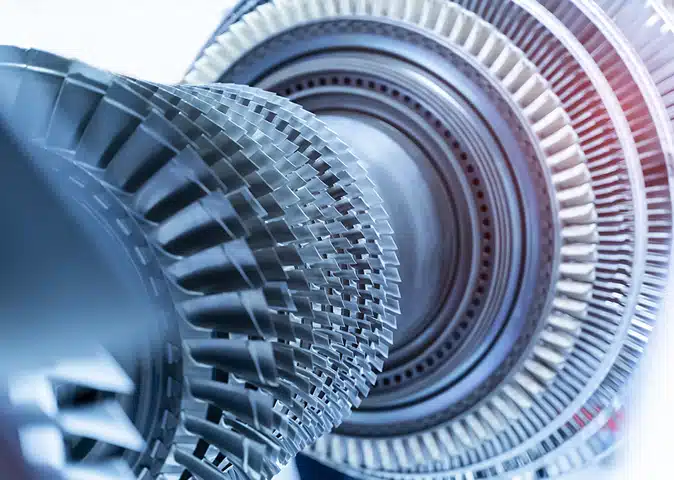

What is an Automated Riveting Machine?

An automated riveting machine is designed to join components using rivets, operating autonomously or with minimal human input. These machines ensure accurate and consistent fastening, which is critical in high-volume production. By automating this process, companies can reduce errors, increase productivity, and maintain the highest quality standards.

Applications of Riveting Machine Use

The use of riveting machines is widespread across industries where durable and reliable fastening is essential. Here are some of the key industries benefiting from this technology:

- Automotive: Used for assembling panels, seats, and structural components, providing strength and stability in vehicles.

- Aerospace: Critical in aircraft construction, ensuring strong joints to maintain safety and structural integrity.

- Electronics: Helps secure small, delicate parts in devices like smartphones and laptops with precise, controlled fastening.

- Construction and Infrastructure: Ensures lasting joints in large-scale projects, such as bridges, building facades, and metal frameworks.

Key Benefits of Using an Automated Riveting Machine

1. Increased Production Speed

Automated riveting machines perform fastening tasks quickly and efficiently, allowing manufacturers to meet high production targets without delays.

2. Precision and Consistency

These machines guarantee uniform rivet placement, ensuring each product meets the same high-quality standards.

3. Cost-Effective Labour Management

Automation reduces the reliance on manual labour, allowing businesses to focus their workforce on more complex or creative tasks.

4. Enhanced Safety in the Workplace

With less human involvement in the riveting process, the risk of injuries decreases, promoting a safer work environment.

5. Versatility Across Applications

Modern machines can accommodate a range of rivet types and materials, offering flexibility for businesses with varied production needs.

Industrial Riveting Machine: Built for High-Demand Operations

The industrial riveting machine is designed for large-scale production environments where reliability and performance are paramount. These machines can handle a variety of materials, ensuring secure and efficient fastening for high-demand operations.

Expert Technologies Group offers bespoke industrial riveting machine solutions, helping businesses optimise their processes with advanced equipment tailored to meet specific requirements. Their machines provide durability and consistent results in even the most challenging environments.

Technological Innovations in Riveting Systems

The automated riveting machine continues to evolve, with innovations enhancing its capabilities and usability:

- IoT-Enabled Machines: Real-time monitoring and diagnostics help maintain consistent quality and prevent downtime.

- Robotic Integration: Automated riveting systems can work alongside robotic arms, enabling fully automated production lines.

- Energy-Efficient Designs: Newer machines are built with sustainability in mind, lowering operational costs and environmental impact.

Why Choose Expert Technologies Group?

Expert Technologies Group provides advanced automated and industrial riveting machines, known for reliability and innovation. They offer tailored solutions to meet the specific challenges of each client’s production process.

By partnering with Expert Technologies Group, businesses benefit from:

- Customised Solutions: Machines designed to meet individual production goals.

- Technical Expertise: Ongoing support and maintenance to ensure smooth operations.

- Access to Cutting-Edge Technology: Innovative solutions that help businesses stay competitive.

Conclusion

The automated riveting machine is a vital tool for manufacturers looking to improve efficiency, precision, and safety. Its use spans industries such as automotive, aerospace, electronics, and construction, ensuring reliable fastening solutions across diverse applications.

Expert Technologies Group’s advanced solutions empower businesses to optimise their operations, reduce costs, and enhance product quality. Investing in automated and industrial riveting machines is essential for staying competitive in today’s fast-paced manufacturing environment. With the right technology and support, companies can achieve long-term success and maintain a leading position in their industry.