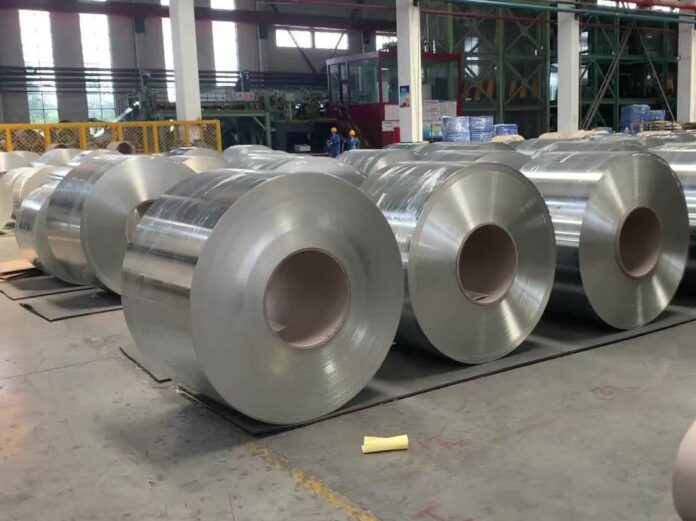

202 stainless steel (SS) coils are widely used in various industries due to their excellent corrosion resistance, strength, and cost-effectiveness. Proper maintenance ensures these coils retain durability, aesthetic appeal, and functionality. Below are essential maintenance tips to keep 202 SS coils in optimal condition:

Regular Cleaning Practices

Regular cleaning is crucial to maintaining the performance and appearance of 202 SS coils. Dirt, dust, and other contaminants can accumulate on the surface, leading to staining or corrosion over time.

Use Mild Cleaning Agents: Clean the surface using warm water and a mild detergent. Harsh chemicals can damage the protective chromium oxide layer on the stainless steel.

Avoid Abrasive Materials: Use soft cloths or sponges for cleaning. Avoid using steel wool or abrasive pads that can scratch the surface, as scratches may trap contaminants and lead to rust formation.

Rinse Thoroughly: After cleaning, rinse the coils with clean water to remove any residue. Residual cleaning agents can cause discolouration or staining over time.

Protecting Against Corrosion

Although gyros 202 SS offer excellent corrosion resistance, exposure to harsh environments or improper handling can compromise their protective properties.

Minimize Exposure to Chlorides: Chloride ions in saltwater and specific cleaning agents can cause pitting corrosion on 202 SS coils. Rinse the coils promptly if they come into contact with chlorides.

Apply Protective Coatings: In highly corrosive environments, a thin layer of protective coating, such as a specialized stainless steel polish, enhances resistance against rust and stains.

Store Properly: Store the coils in a dry, covered area away from moisture, chemicals, or extreme temperatures. Proper storage reduces the risk of corrosion during idle periods.

Preventing Surface Stains

Surface stains can form on 202 SS coils due to exposure to contaminants or improper handling. Preventing stains ensures that the coils maintain their clean and polished appearance.

Handle with Clean Gloves: Use clean gloves or tools when handling the coils to prevent oils and dirt from transferring to the surface.

Remove Fingerprints and Smudges: Clean fingerprints or smudges promptly using a stainless steel cleaner or a mixture of water and vinegar. Wipe in the direction of the grain for a streak-free finish.

Avoid Contact with Iron or Steel: Avoid placing the coils in direct contact with iron or carbon steel materials, which can lead to surface contamination and rust.

Inspecting for Damage

Regular inspections are essential to identify any signs of damage or wear early, allowing for timely intervention.

Check for Scratches or Dents: Scratches or dents can compromise the structural integrity of the coils and make them prone to corrosion. Repair or replace damaged sections as needed.

Monitor for Discoloration: Discoloration may indicate overheating, chemical exposure, or improper maintenance. Address the underlying cause promptly to prevent further damage.

Inspect Edges and Corners: Edges and corners are more vulnerable to damage. Ensure these areas remain smooth and free from corrosion.

Maintaining Polished Surfaces

Many applications require 202 SS coils to maintain a polished or mirror-like finish. Proper care preserves the aesthetic appeal and functionality of the coils.

Use Specialized Polishing Products: Apply stainless steel polishing compounds to restore the original shine and remove minor scratches or stains.

Buff with Soft Cloths: Buff the surface gently using a soft, lint-free cloth to enhance the polish without causing scratches.

Avoid Over-Polishing: Excessive polishing can wear down the protective oxide layer, reducing corrosion resistance.

Preventing Thermal Damage

In high-temperature applications, thermal damage can weaken the structure and appearance of 202 SS coils.

Monitor Operating Temperatures: Ensure the coils are used within their recommended temperature range. Excessive heat can cause discolouration or warping.

Cool Gradually: Allow the coils to cool gradually after exposure to high temperatures to prevent thermal shock, which can cause cracking or deformation.

Routine Maintenance Schedule

Establishing a routine maintenance schedule ensures consistent care and prolongs the lifespan of 202 SS coils.

Weekly Cleaning: Perform basic cleaning weekly to remove surface contaminants.

Monthly Inspection: Inspect the coils for signs of damage, discolouration, or corrosion.

Annual Polishing: Conduct a detailed polishing session annually to restore the surface and maintain the appearance.

Proper Disposal of Cleaning Residues

Responsibly dispose of cleaning residues, such as water, detergents, and polishing compounds. Avoid leaving residues on the coils, as they may cause staining or other surface issues over time.

By following these maintenance tips, you can maximize the performance and lifespan of 202 SS coils, ensuring they remain durable and functional for various industrial and commercial applications.